Safety measures for roof management during initial mining and initial release

According to the analogy analysis of the top plate of the surface, the initial pressure step is 15~30 meters. 1. The company set up a preliminary team for the initial release, and the overall team is responsible for coordinating the work and release of the work. According to the “good equipment standardâ€, all the electromechanical equipments on the working surface will be inspected one by one to ensure that all electromechanical equipments are well lubricated, the oil level and pressure are normal, the protection devices are complete and reliable, and the wiring meets the standards to prevent explosion. Starting from the initial release and preliminary release, the progress of the initial release of the safety work on duty should be recorded in detail, and the dispatching room or the team leader of the initial mining and preliminary release team should be reported in time. 2. After the installation and acceptance of the working face, the leading group of the initial mining and preliminary release is responsible for the single-machine test operation of all the equipment on the working surface, and debugging. When the single machine is running normally, the joint test operation is carried out in the order from the outside to the inside to ensure the joint test operation. The equipment is operating normally during the initial mining. 3. When the roof of the tail beam of the bracket is fallen, the coal can be discharged from the bottom to the top. The amount of the coal is not more than 30% of the total amount of the top coal. As the work advances forward, the amount of top coal is gradually increased. 4. The working face is pressed, the direct top is behind, the top coal is released, and the filling height is guaranteed. The roof is bent, sunken and broken, that is, the working face begins to pressure. Normal coal mining, during the initial mining of the working face, the top coal outflow rate in the range of 20m reaches 50%. 5. During the lottery period, in accordance with the provisions of the “Operation Regulationsâ€, the stope is set up, and the end and two advanced support are strengthened. The pillars are intact, the boots are worn, and the stigma is tied reliably. 6. Strictly move the frame according to the cycle schedule, support the roof in time, and minimize the empty top area and the end face distance. 7. When the work surface appears to suppress the warning, strengthen the follow-up inspection, strengthen the support, report and record in time to pressure the situation. 8. During the initial mining period, the equipment maintenance is strengthened. The emulsification pump and hydraulic system are intact and no sputum sputum. The pump station pressure reaches 30Mpa and the emulsion concentration reaches 3~5%. 9. When the working face is pressed, try to speed up the advancement until the first pressure is applied. 10. If the working face is opened and cut, if the top coal is still not falling, it is necessary to force the top until the top plate is completely fallen. 11. When the working surface cycle is before and during the pressure, strengthen the working surface and the management of the two roofs, and strictly prevent the front and rear scraper conveyors from being crushed and the front scraper. 12. Strengthen the upper and lower end support during the initial mining and initial release to ensure unimpeded flow, and the pedestrian width is not less than 0.7m. 13. Reserve a sufficient amount of support material for the two lanes during the initial mining and preliminary release to support the pressure. 14. During the initial mining of the working face, the two advance support distances shall not be less than 40 meters to strengthen the support. 15. Two pedestrians in the working face, unobstructed ventilation, and reserve the grease, wearing parts maintenance tools and spare materials needed for the shift at the designated place. The ventilation, dustproof, fireproof and gas-proof facilities of the fully mechanized caving face must be complete. And in line with the "Safety Regulations for Coal Mines" and related documents. 16. During the initial mining period, if the pressure does not appear to be very severe, the working surface advancement should be slowed down, and the bracket should be lifted repeatedly so that the top coal can be broken early. 17. According to the above method, only when the leading group or technicians are on-site to identify and determine the initial release of the initial mining, all the processes on the working surface can be carried out normally according to the “Operation Regulationsâ€. 18. During the initial mining period, strictly follow the production process stipulated in the “Operation Regulationsâ€. When coal is cut, if the coal wall pressure is high, there is a roof. When the film is waiting for the omen, the front bracket must be pulled out in time to extend the front beam and the guard plate. Pedestrians are strictly prohibited near the coal wall. 19. All brackets on the working surface must ensure sufficient initial support. 20. During the initial mining period, strictly control the quality of the working surface. When using the laser pointer or the working surface, ensure that the brackets are straight and straight. At the same time, pay attention to adjust the spacing of the brackets to prevent the occurrence of backing and biting. 21. The working face shall check the gas concentration during the initial mining and work recovery period no less than 2 times per shift. Categories Pneumatic Cylinder Kits,Air Cylinder Kits,Pneumatic Air Cylinder Kits,Aluminum Cylinder Kits Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com

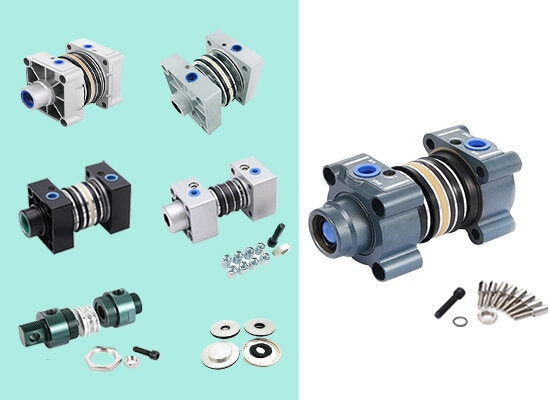

Cylinder assembly accessories include one front cover and one rear cover, one piston, two Y-type piston seals, one hard-wearing ring, one set of magnetic rings (some cylinders do not have magnetic rings), two cylinder seal O-rings, one piston rod sealing ring, one dustproof, two buffer caps, two buffer screws (with O-ring), one piston rod end thread, one piston fixing bolt, 8 fixing bolts, dustproof air inlet and outlet two caps, one piston rod end thread protection cover.Air Cylinder Tube.

Because the different application needs different strokes of air cylinders, for dealers and distributors, storing a large number of cylinders with fixed strokes will occupy a large amount of inventory funds.Pneumatic Cylinder Tube.

However, storing the Pneumatic Cylinder assembly parts can solve this problem very well. When requires different strokes and then temporarily assembling the cylinder accordingly.Air Cylinder Barrel.

Common cylinder assembly parts include DNC square cylinder series, ISO standard Metalwork series, SI Mickey Mouse type ISO 15552 cylinder series, SC and SU AirTac standard cylinder series, SDA compact cylinder series, and DSN, MA, MAL mini air cylinder series, etc. .

Matters needing attention when assembling the cylinder

For non-professional cylinder manufacturers, we do not recommend self-assembly to avoid problems caused by incorrectly assembling cylinders.

The following points need to be paid attention to when assembling an air cylinder by yourself:

â—† The inner edge of a pneumatic cylinder needs to be chamfered to facilitate the entry of the piston and sealing ring into the cylinder tube.

â—† Before assembling the piston and cylinder, lubricating grease must be applied to the inner wall of the cylinder to reduce the friction between the sealing ring and the inner wall of the air cylinder.Pneumatic Cylinder Barrel.

â—† The edge of the piston rod end also needs to be chamfered to reduce damage to dust and buffer seals.Pneumatic Cylinder.

â—† Because the end of the piston rod has external threads, special attention should be paid when assembling the piston rod and the front end cover. It is necessary to use the end of the piston rod without threads to pass through the gasket. Otherwise, the inner wall of the gasket is easily cut by the threads and resulting in an air leakage.

â—† For the installation of the tie rod cylinder, it is also necessary to pay attention to the position of the tie rod thread, so that there is enough thread space in the fixing bolts of the front and rear end covers to install the cylinder accessories such as CA, CB mounting brackets, FA/FB flange brackets.Cylinder Tube.